Guangzhou is a large city on the southern shore of China. Across the Greater Bay lies Hong Kong. Guangzhou is mainly a port and trade city, part of both the historical and current Silk Road. Together with eight other cities (including Shenzhen), Macao, and Hong Kong, it forms the Greater Bay Area megalopolis, the second largest urban area in China (and the world), after Shanghai and its surroundings. Guangzhou is one of the few multicultural cities in mainland China, harboring for instance a large African community.

Being a port city with excellent international connections and its proximity to Hong Kong have made Guangzhou the center of less legal car trade from time to time. During several periods Guangzhou was the focal point for smuggling cars into China, sometimes condoned by the party officials. Making cars in the city is a much more recent thing. We’ve already seen that Dongfeng-Nissan has a large presence, but the city also has its own car industry, named GAC. In the next few episodes, I’ll walk you through the history of this company.

Let’s start the story right in the middle. On June 21, 1997, the Guangzhou city council established Guangzhou Automobile Group Ltd (GAG). This wholly state-owned entity appeared to unify the car-producing factories in the city under a single holding and would later be renamed GAC. Most car-related industries were then part of one of three, also city-owned groups: Yangcheng Automobile Group, Guangzhou Guangke Automobile, or Guangzhou Denway (Junwei) Automobile. Yancheng made light trucks, Guangke was a consortium of several bus factories and Denway also made buses and had just ended its passenger car production. All three groups find their origins in the 1940s and 1950s, so let’s look back a little further.

Guangke, the bus industry

Guangzhou is quite an industrious city, but it lacks the large steel works or petrochemical plants that fuel the car industry in other places. So, during the early years of the People’s Republic Guangzhou’s car industry revolved around several repair shops and small part makers. There were only a few passenger cars around, so these repair shops got their income mainly from keeping the public transport system rolling.

One of these repair shops was the Automobile Repair and Assembly Factory from the Guangzhou Transportation Board, established in 1949. In 1954 the factory also started assembling new buses with wooden bodies under the Huanan brand. That changed to Yuexiu brand (and steel bodies) in 1963 and later to simply Guangzhou brand. This factory was one of many that also manufactured a derivative of Beijing BJ212 off-roader, a wagon version called GZ215. This took place in the 1970s. In 1975 and 1976 the factory also made two passenger cars, both sedans that resembled the Japanese designs of the time. Not much is known about these cars and I only have two very low-resolution images.

The passenger car production didn’t stick and by 1984 the factory had changed its name to Guangzhou Bus Factory. In 1980 another workshop turned into a bus manufacturer, called the Guangzhou Nanhua Bus Factory. In 1987, Nanhua was acquired by Guangzhou Bus and the two formed the Guangzhou Bus Group almost ten years later, otherwise known as Guangzhou Guangke Automobile Enterprise Group.

A third bus manufacturer in the city, that originated in 1949, was initially controlled by provincial authorities and called the Guangdong Provincial Transport Bureau Bus Factory. The company made buses under the Zhujiang brand, named after the Pearl River that cuts through Guangdong. In 1984 the company name was shortened to Guangdong Bus Factory. In 1999 this factory became part of Guangke, that in turn was now controlled by GAG.

The Guangke bus factories held little intellectual property of their own. They usually sourced a rolling truck chassis, often from Dongfeng, and their own bodies. But the bus market was changing and competitors started using dedicated bus frames to introduce more advanced products. To keep up GAG transformed Guangke into a joint venture with Isuzu, the Japanese commercial vehicle manufacturer. This took place in March 2000 and the joint venture lasted for eight years. Then Isuzu pulled out to concentrate on its other Chinese joint ventures. GAG (or GAC by then) merged the remains of the company with Denway’s bus division and the company became GAC Autobus Co., Ltd.

Yangcheng, the truck maker

In 1958 a group of 79 small, almost household businesses was unified as the Yuexiu General Machinery Factory. These businesses mostly made small components and since many of them were related to the car industry, the collective changed name in 1962 to Guangzhou Yuexiu Automobile Repair Factory. Yuexiu, by the way, is a neighborhood in Guangzhou, but the factory lost the geographical reference somewhere during the Cultural Revolution. In the 1970s it was known as the Guangzhou No. 2 Automobile Repair Factory.

Apparently, it started making complete vehicles as well around that time, as the factory is credited to be one of the first with full production qualifications in the city. Unfortunately, I can’t find for certain what kind of vehicles that might be. I guess they most likely made Guangzhou-branded buses, like Guangke, but I can’t find confirmation of that.

So, let’s skip forward to 1987 because from then on we can confirm the direction of the company. In that year Guangzhou No. 2 Repair Factory closes a deal with the Jiangxi Automobile Factory for technology transfer and licensing. Jiangxi Automobile is the predecessor of the JMC Company and at that time already cooperating with Isuzu. The technology transfer includes Isuzu’s N-series truck, also known as the Elf. In 1989 the repair factory changes its name to Yangcheng Automobile Factory and production of the Isuzu-licensed trucks starts in 1991. The brand is Yangcheng, but the trucks feature the name YCACO on the grille.

A year later, Yangcheng Auto and Guangzhou City jointly create Guangzhou Yangcheng Automobile Co., Ltd. This company is the result of ongoing negotiations with Honda to establish some kind of passenger car production in the city. The details of this story will follow later on. At this point, it’s sufficient to know that the deal does not come off the ground and Yangcheng’s car production is limited to importing some Honda Accords as knockdown kit.

In 1997 the entire Yangcheng Automobile Group comes under the control of GAG and it remains a light truck manufacturer. The technical cooperation with Jiangxi Isuzu remains in place for another ten years. By then the Isuzu N-series trucks are made by a wide variety of larger and smaller Chinese companies and GAG looks for a more profitable direction of the company. The opportunity arose through Hino, the Toyota-owned truck manufacturer. GAG had formed a joint venture with Toyota just a few years earlier.

Hino was already active in China. Since 2002, they had a joint venture with Shenyang Shenfei Automobile, a bus maker up north, that was established in 1993 but enjoyed little commercial success. In 2008, GAG turned Yangcheng Automobile into a joint venture with Hino and bought all of Shenfei’s interest in the Shenyang enterprise. The result was GAC Hino Co., Ltd. The name Yangcheng disappeared and the joint venture made Hino buses in Shenyang and Hino trucks in Guangzhou. But even under the new ownership, the bus company didn’t turn profitable and in 2016 the Shenyang factory was closed.

In Guangzhou, Hino took over the Yangcheng factory and so the Isuzu-based trucks were removed from the line-up. Instead, it started making the Hino 700-series truck. This is a heavy truck that GAC Hino still makes today in a wide variety of configurations, including tractors and dump trucks. Sales and production hover around 5.000 trucks per year.

Denway, from the steam era

It’s probably weird to see an English name for a Chinese company, but that has all to do with a listing on the Hong Kong stock exchange. There is however a long way to go before we get there.

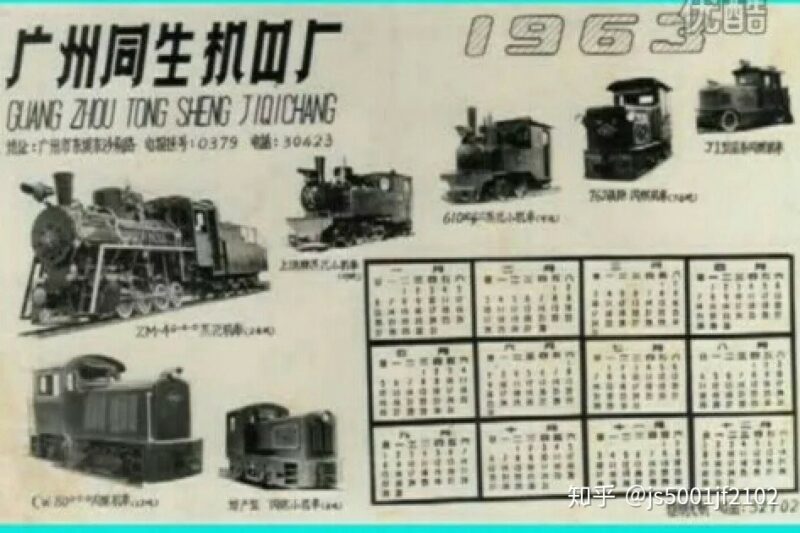

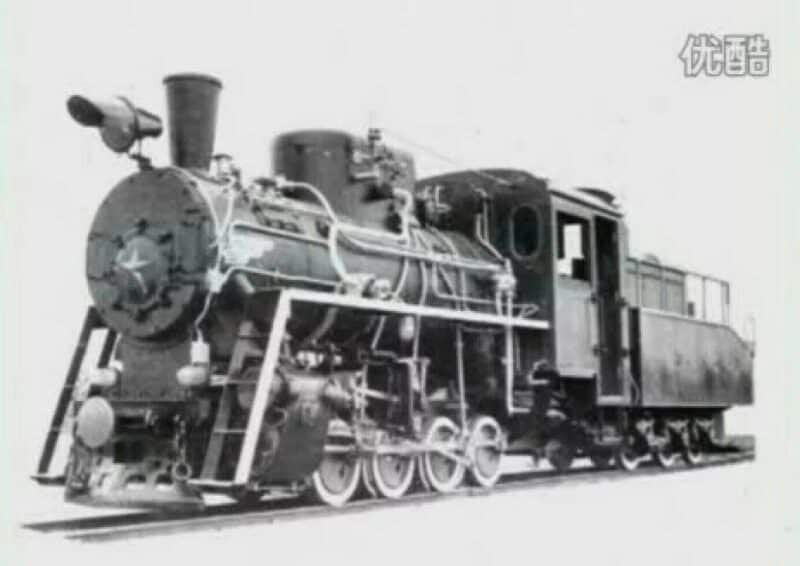

In the course of these Automaker Stories, we have seen quite some different origins for China’s car manufacturers. Usually, they grew out of repair shops or military workshops, but we’ve also seen makers of agricultural machinery, ammunition, or aircrafts migrate into the car industry. Today we add a new product category: steam locomotives. By now, you have probably concluded that GAC has quite fuzzy origins (like several Chinese car makers), but the straightest line from today’s cars to the actual starting point leads to a company called Tongsheng Machinery Factory.

Tongsheng was founded in November 1948, a few months before the communists conquered the city. The company was set up to provide rolling stock for China’s narrow track (i.e. 762 mm) railways, one of which happened to run through Guangzhou. In the next fifteen years or so, Tongsheng built a variety of steam locomotives, but by the early 1960s, the steam era was ending in China as well. So Tongsheng started looking for new things to make.

In 1965, Nanjing Automobile trial produced a light truck called Yuejin WD35. This truck was based on an American International Harvester chassis, but equipped with a front steer cabin. After trial production, Nanjing Auto decided not to push on with the design. The drawings for the truck ended up with Zhejiang Transportation Co., Ltd. Automobile Repair Factory in Hangzhou, which produced it as the Qiantangjiang truck and at Tongsheng. The latter started production in September 1969 and named it Hongwei GZ140. Just before launch, Tongsheng changed its name to Guangzhou Automobile Factory.

The Hongwei was a 3.5-ton truck and remained unchanged for many years. In 1976, Hongwei added a slightly larger version, the 4-ton GZ141. The last derivative appeared in 1980, the GZ141B was a long wheelbase version of the 4-ton Hongwei. By then the design was showing its age and sales were declining. So after 12 years of production and about 11.000 trucks sold, Hongwei discontinued the GZ140 and GZ141 series in 1981.

Instead, the Guangzhou Automobile Factory made a technology deal with Dongfeng. Like the Hangzhou Repair Factory, it became affiliated with Dongfeng’s industry joint venture fund, which tried to secure a supply chain for the Hubei-based company and became the basis for the conglomerate it is today. The Hangzhou Factory ultimately became part of Dongfeng, but Guangzhou only did a cooperation agreement. Dongfeng supplied truck frames and Guangzhou Auto built buses on top of them. So, Guangzhou Auto became yet another bus manufacturer, like Yangcheng and Guangke. The brand name was Junwei, which transliterated to English, later became Denway.

Bonjour Peugeot

Meanwhile, the central government in Beijing had formulated a joint venture strategy for the car industry. In the early 1980s the first results of the economic reforms became visible and a ‘car fever’ swept the country for the first time. Cars were in short supply and the basic industry was lacking. So, the federal government bet on joint ventures with foreign car companies to quickly build capacity and strengthen the technology foundations of its own industry. We now know that this worked out quite well.

Within this framework, officials in Guangdong saw the opportunity for a relatively small-scale project. In early 1984, the governor of Guangdong and the mayor of Guangzhou together traveled to Beijing and proposed a project for 10.000 pickups per year to the State Planning Commission. The Commission agreed to the project almost immediately and the formal joint venture company was set up (in September). In fact, briefing the State Planning Commission was done after the deal had been concluded. Guangdong officials had been in contact with their planned partner, Peugeot from France, for several years and all formal contracts were signed a week after the permission in March 1984.

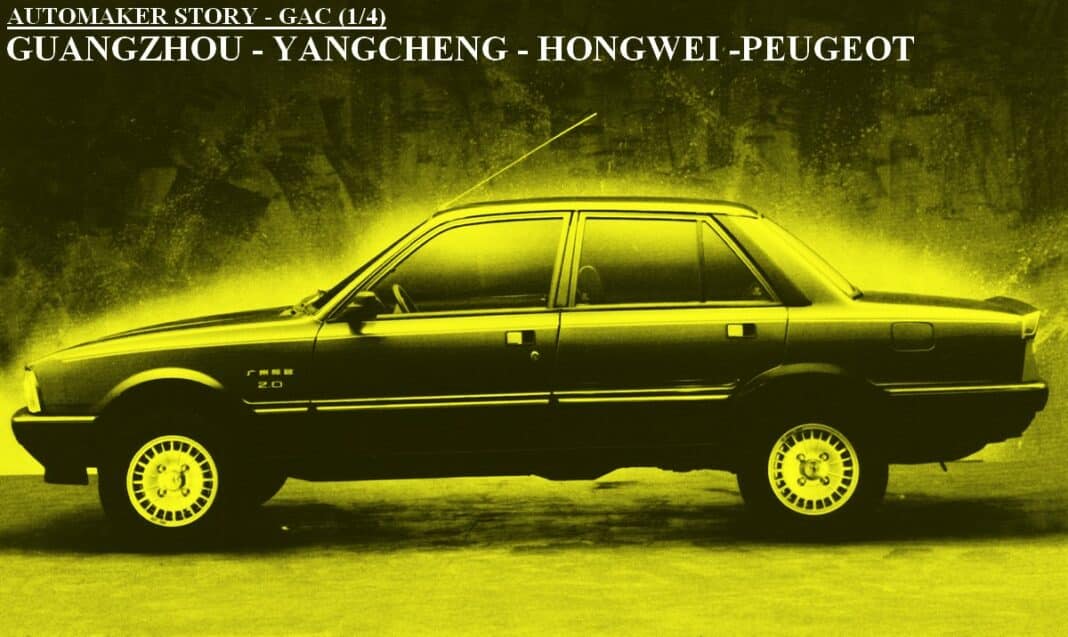

Although Guangzhou Peugeot Automobile (GPA) was only the third automotive joint venture (after Beijing-Jeep and SAIC-VW), it was already deviating from the regular, as a lot of financial institutions were part of it. Guangzhou Automobile Factory held 46% of the shares, Peugeot 22%, CITIC (a China state-owned development fund) 20%, IFC (a Worldbank-owned development fund) 8%, and French bank BNP Paribas 4%. Although Peugeot held a minority share, it gained actual control over the company. Peugeot could name enough directors for a blocking minority (meaning they could veto any decision), and could name the general manager and at least one of two managers in each important department. This setup was partly responsible for the troubles that would soon arise.

A French colony

Peugeot came from a somewhat difficult position. In the years prior, the company was loss-making and had trouble keeping its French factories at work. So it entered GPA, as it did with some operations in Africa, in what could be called “colonial style”. Peugeot saw GPA primarily as an opportunity to increase production in its own factories and ship CKD kits overseas for a nice profit. And that’s what happened at first. The Peugeot 504 pickup was the first model, soon followed by the 505 station wagon. GPA targeted taxi companies and government agencies and got off to a promising start. Production increased from 2.000 units in 1985 to 5.000 in 1988.

Peugeot installed a basic welding and assembly line in Guangzhou with an initial capacity of 15.000 cars per year. With production steadily increasing, GPA applied for and received permission for a stage 2 development in 1989, doubling capacity and allowing the 505 sedan to be added. This extra capacity was a welcome addition, as production continued to grow and reached well over 20.000 cars in 1993, a 15% share of the Chinese car market. At the time no one realized this would be the peak of the company, but the signs that trouble was brewing, were already there.

The relationship between the French and Chinese was strained from the very beginning. The Chinese disliked the French for controlling everything and not taking their advice on certain matters. The French had a hard time with the “communist work mentality” and the lack of straightforward communication. Both sides could overcome the distrust between them when GPA was performing well, but when things became more difficult, these differences exaggerated the problems.

There were two major obstacles. First, China’s joint venture policy stipulated that a certain percentage of production must be localized. And second, China updated its policies in 1993, adding the requirement that international joint ventures must have a capacity of 150.000 vehicles annually by 1996. Let’s analyze both challenges.

The localization issue had two sides. First, Peugeot wanted to keep using knockdown kits as much as possible, because it boosted the profits of the main company and kept its French factories at work. Secondly, there were very few qualified workshops in the Guangzhou area capable of making quality parts at the required pace. So Peugeot kept pushing GPA to import the main products from France and the components that were localized, were of low quality. This harmed the reputation of the brand because the cars became known for bad reliability and very expensive repairs since spare parts were imported from France.

The capacity issue went right to the heart of the financials of GPA. During the first stage of the company, Peugeot made a significant investment in updating the factory and installing the assembly line. But for the subsequent stage 2 upgrade in 1989 and stage 3 required by the new regulations, it expected GPA to finance a much bigger part of the package. GPA had not returned a profit by then, and frankly, it would never do so.

In fact, the financial situation had already led to some changes on the Chinese side. In 1988 Guangzhou Automobile Factory was incorporated as Guangzhou Automobile Group Corporation (GAGC, not to be confused with the 1997 GAG). In 1992 GAGC set up a Hong Kong-based holding company called Denway Motors and listed that company on the Hong Kong stock exchange to raise some funds. The Guangzhou City Council remained in control through an intermediate investment holding called Zhonglong (China Lounge), which held on to 38% of the Denway shares. This listing took place unbeknownst to Peugeot.

This way, GPA acquired the funds for the stage 3 expansion, but there was an additional challenge. The renewed government regulations also required an engine assembly line and this was something Peugeot didn’t really want. So when inspectors from the State Planning Commission visited GPA for the stage 3 expansion project, they found a disassembled engine with parts laying around on the floor and laborers working on it without any professional tools. The Chinese weren’t fooled and denied the application for the factory upgrade.

Over in Shanghai, Volkswagen had taken to the opposite route. They engaged with the Chinese and build a local supply chain. Shanghai-VW production surpassed 100.000 in 1994 and reached almost 150.000 the next. At the same time, government officials preferred the Audi 100 rolling out of the Hongqi factory over the slightly outdated Peugeot 505. The French had not spent a lot of time or money on product development or promotional activities and now it backfired. After 1993, Peugeot sales collapsed while GPA kept piling up debt.

Well, that can’t be good. We’ll see how it all pens out next week.